The tradition of Shoto dates back to the early 1960s when the Medori family in Montegranaro, in the heart of the Marche region (Italy), began producing handmade shoes. Even after years, the third generation of the Medori family continues to drive innovation and aesthetic research while preserving the heritage of their expertise in shoemaking and the enthusiasm of beginners for the craft. The unique company culture, focused on high quality, reflects the personality of the founder, Graziano Medori. As an independent shoemaker, he opened the first factory with employees responsible for manufacturing classic-style shoes. These were essentially handmade and targeted at the local market.

The year 1985 marked one of the turning points in the company's history with the introduction of the new brand "Shoto," which was entirely conceived and developed by the third generation of the Medori family. The identity of the Shoto brand was definitely new to the market. It was a forward-thinking product with its unique lifestyle philosophy. It appealed to an audience of creative and bold individuals with strong personalities, a clearly defined "physique du rôle," and a special passion for creative elegance, sobriety, and high quality.

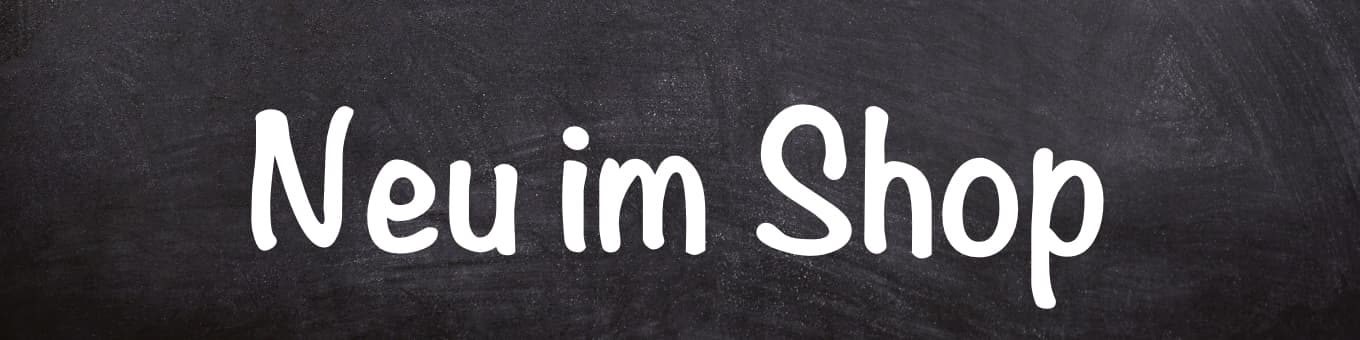

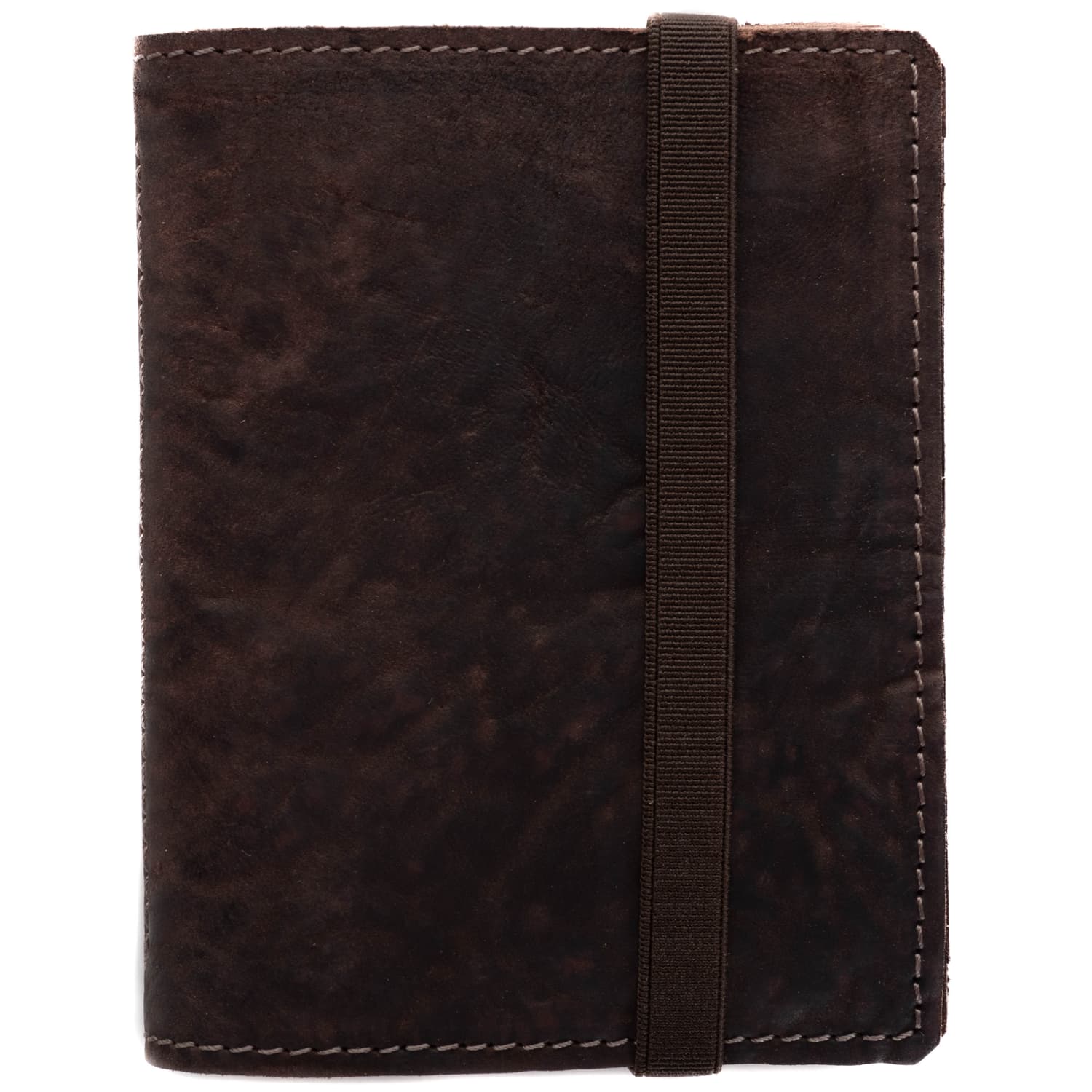

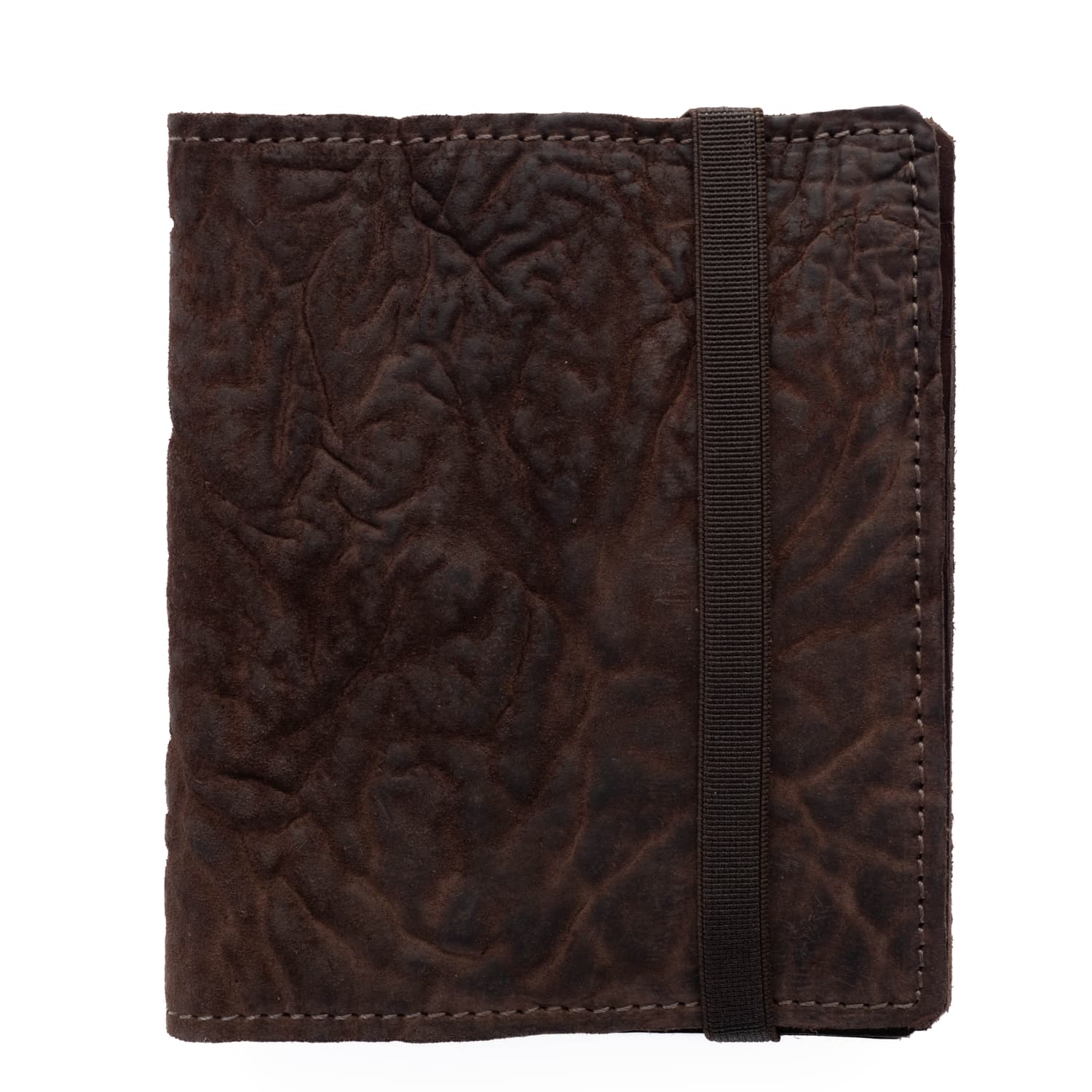

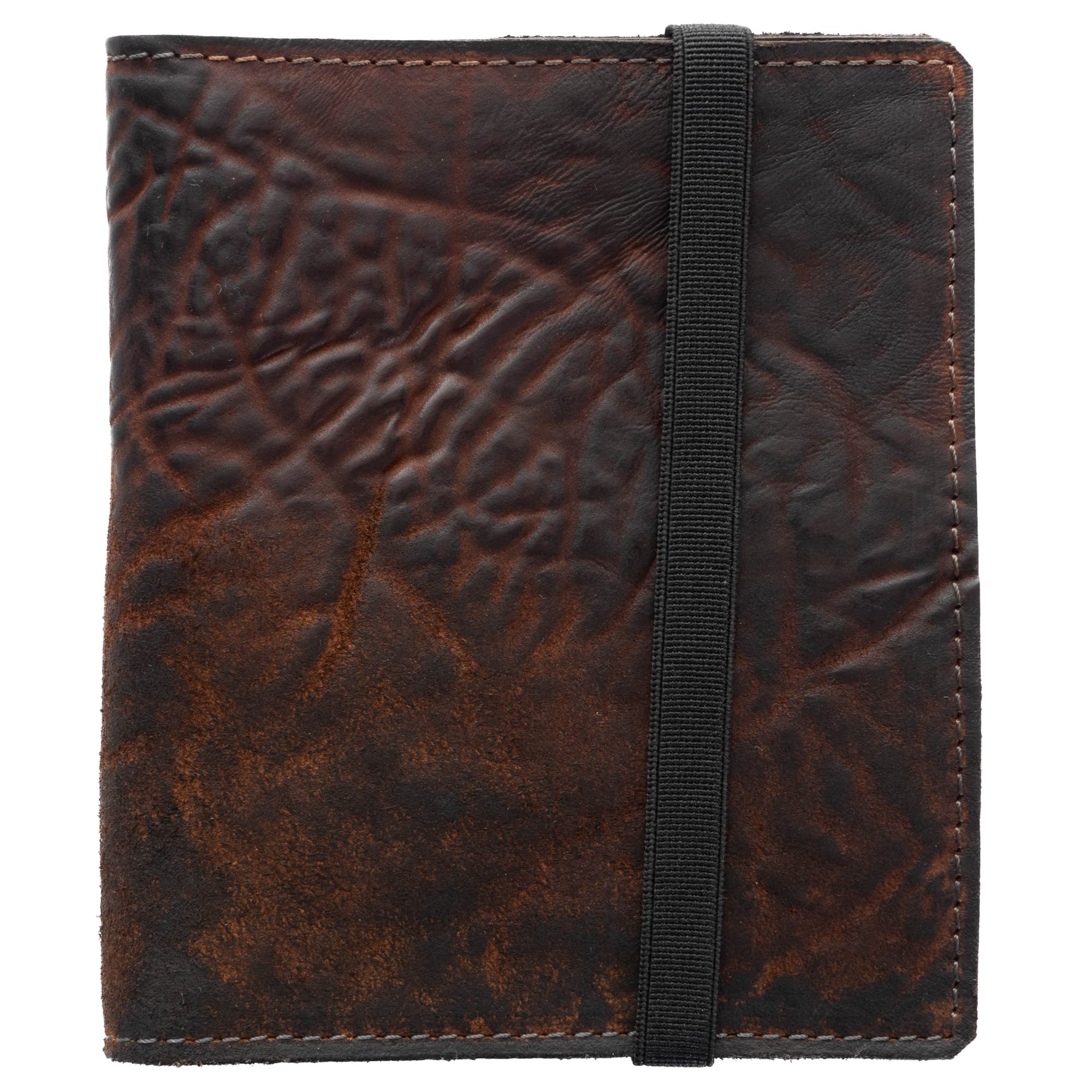

The Medori family, which has been manufacturing shoes for decades, has recently ventured into uncharted territory by also producing wallets and bags.

The Shoto Sterling collection, which chronologically falls between shoes and wallets, is lovingly handcrafted by Mrs. Ritter in Germany. More on this below under Shoto Sterling.

The Shoto wallets and bags were introduced in 2017 and 2019. Here, the premise is the same as with the shoes – to create a high-quality, unique product that is durable and brings great joy to both men and women.

The Passion is Shoes

Simone and Stefano Medori have not only been passionate about fine footwear since the founding of Shoto in 1991 (their story dates back to the 1960s). Under the Shoto label, they craft shoes with vintage effects of the highest quality, using special leathers and manufacturing techniques.

In addition to elk, buffalo, horse, and kangaroo leather, and alongside dyeing techniques such as dip-dyeing, dabbing, and wring-dyeing, the complete "stone-washed" treatment is applied to the shoe. Options like Caos, Vintage, Oldwash, Pablo, and many more constantly open up new possibilities to create a unique and incomparable shoe.

The manufacturing techniques are rooted in traditional craftsmanship. Every wearer can immediately feel this when trying them on.

Manufacturing

All shoes are handcrafted in Italy. Depending on the model, type of leather, color, and finish, the manufacturing process varies.

During the "Stone-Wash" process, the entire shoes are washed with stones in an oversized washing machine.

In the dip-dyeing process, the leather of the shoe (and the laces) is dipped into a barrel with the corresponding color and then hung up to dry for up to 24 hours.

Video from Production In the following video, you will gain insights into the manufacturing processes of Shoto. The dip-dyeing and the so-called "stone-wash" process are particularly well visible.